Demister bathroom mirror - StopVapor

StopVapor mirror demister when in operation prevents steam from condensing on the mirror surface. Suitable for application on mirrors in humid environments and without windows such as gyms, swimming pools, hotels and homes.

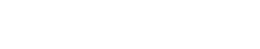

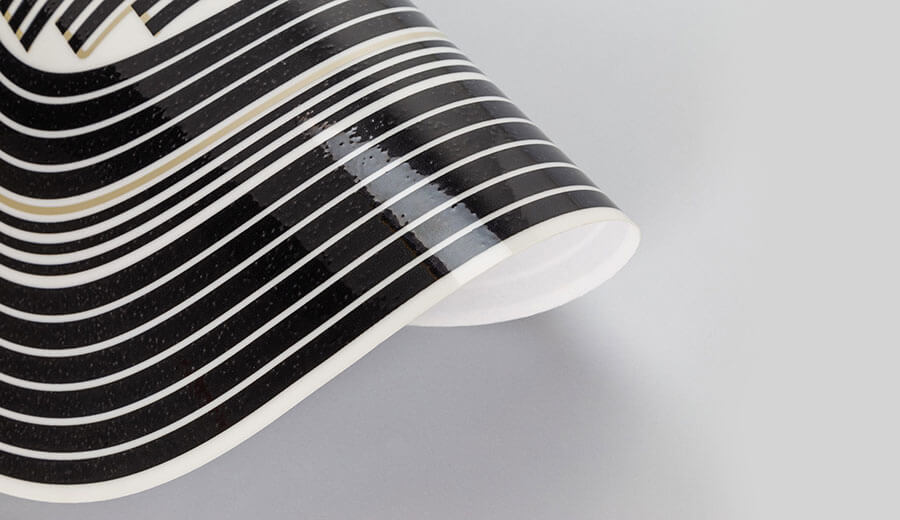

Alper mirror defogger is easy to apply, thanks to the self-adhesive it adheres perfectly on the back of the mirror.

Alper can customize the mirror defogger according to customer specifications. StopVapor is also available in standard sizes to adapt to any type of mirror with square, rectangular or round shapes.

CONTACT US for more information about our StopVapor products

StopVapor bathroom mirror demister guarantees a perfect clear mirror surface, corresponding to the dimensions of the heating foil applied on the back of the mirror.

Easy to apply, StopVapor mirror demister pad is self-adhesive: just place it, after removing the adhesive protection, on the back of the mirror at the desired height.

A 1 cm gap between the wall and the mirror is sufficient to allow the power cable to pass through.

Typical standard sizes:

- 16x28 cm 230V 8W

- 28x28 cm 230V 16W

- 41x28 cm 230V 24W

- 40x40 cm 230V 30W

- ø40 cm 230V 25W

- ø50 cm 230V 40W

- 50x50 cm 55W 230V

- 101x44 cm 105W 230V

- 100x60 cm 145W 230V

Alper can produce dimensions according to the customer's projects even for single lots.

- Maximum dimensions: 1000x600mm (various sizes available on request).

- Power and supply voltages on request.

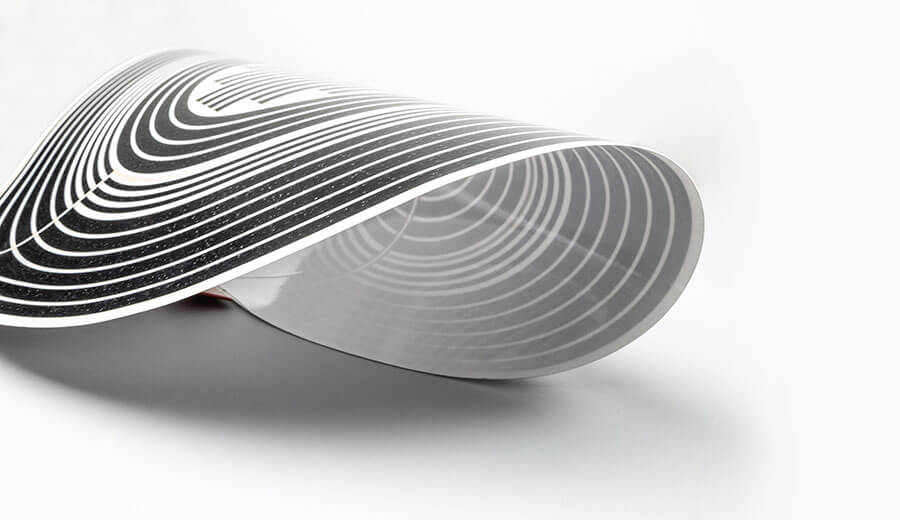

- Excellent temperature uniformity.

- Functionality without the use of thermal protections, such as thermal fuses, thermal protectors, probes and sensors.

- Application of a wide range of double-sided adhesives.

- Wiring on customer specification.

- Class II and III construction.

- 110/230/240V supply voltages and 12/24/48V low safety voltage.

- Customer specific design.

- Min temperature: 35-40 ° C

- Construction according to directive 2014/35/UE

- S.I. 2016 No. 1101 (Electrical Equipment (Safety) Regulations 2016) BS EN 60335-1, BS EN 50106

- UL approval E466385, upon request

- VDE upon request

- RoHS and REACH

Test according to EN 60335-1 and EN 50106