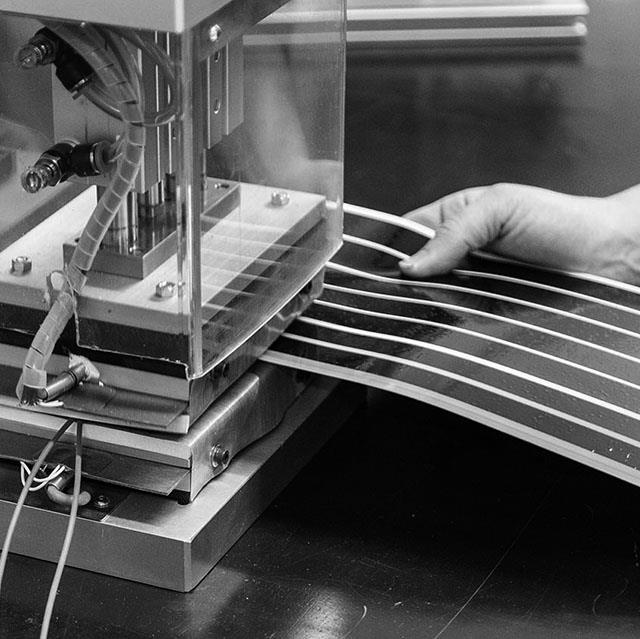

High-tech PTF film elements and flexible printed circuits

Innovation is our strength and our constant promise. Alper’s PTF film elements and flexible printed circuits keep faith with this commitment because, every day, we field the best technology and quality to produce ever-higher performance ultra-flat heating elements, circuits and sensors.

Flexible heaters and circuits of every kind

Alper has developed a series of flexible heaters and circuits with PET (or silicon) backing material to make the product physically flexible and adaptable to all kinds of cylindrical curvature. The advantage? These types of sensors and heating elements are so versatile that they can be used in various goods sectors, and have innumerable fields of use in both the industrial and consumer goods sectors.

The technology of flexible adhesive heaters

Thanks to the use of inks and electrically conductive pastes screen printed on polymeric film, Alper creates resistances of all shapes and with very thin thicknesses, starting from 0.2 mm, suitable for the type of product on which they must be applied. The resistances produced with carbon paste, keeping fixed the size and with only the modification of the composition of the conductive ink, are able to produce different ohmic values up to +/- 20% compared to the design values without any change in the dedicated tooling. The same heaters are suitable to work with a large range of ohmic values and at any temperatures, starting from that of the environment up to about 100°C.

THE 7 ADVANTAGES OF ALPER HEATING ELEMENTS COMPARED TO TRADITIONAL ONES:

- Alper heating elements can be adapted to curved surfaces or inserted in tight spaces because they are printed on a thin, flexible support.

- They can also feature holes or slits for applications that require them.

- They reach the desired temperature quickly and consumption is limited.

- They can provide differentiated heat generation. How? Simply by increasing or decreasing element printing density depending on where and how much you want to heat.

- They stick to a variety of surfaces as one (or both) of the two sides can be made adhesive.

- They’re designed for various types of electrical insulation, according to the environment where they must work.

- They can be produced with any power supply voltage, including low voltage.