Heating resistance for compressors

Alper crankcase heater has a robust construction. An efficient steel knurled belt with draft system allows an easy installation. It can be used in environments where a high IP rating is required. The crankcase compressor has excellent mechanical and electrical reliability both at high and low temperatures.

CONTACT US to learn more about Alper compressor heaters

The use of the crankcase heater proves necessary to preserve the perfect functioning of the compressor.

Alper crankcase heater is the solution that adapts to all needs. It prevents bearing stress and facilitates engine start-up.

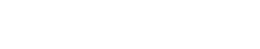

The use of a screw pull hook not only allows for quick installation, but also provides the compressor crankcase heater with excellent adhesion and thus a perfect thermal exchange with the compressor.

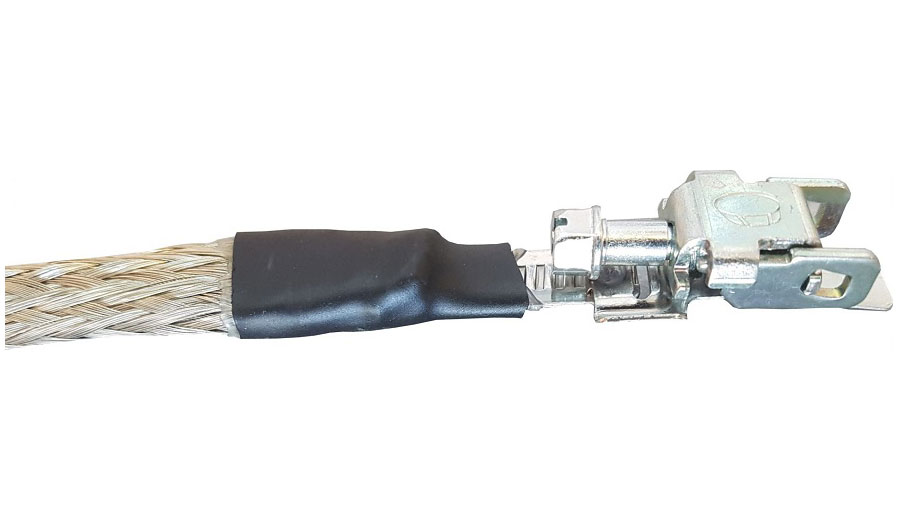

It is possible to manufacture this crankcase heater resistance also according to customer specifications with power cables of different lengths and resistant to UV rays as well as low temperatures.

The compressor crankcase heater can be equipped with protective thermostats and thermal fuses.

Additionally, metallic terminals or other connectors according to customer specifications can be supplied.

- Strap width in AISI 304: 9mm

- Powers: up to 60 Watt/m

- Temperature: -30°C to 180°C

- Compressor diameter: from 100mm to 380mm

- Materials: silicone heating cable / PVC power cable or other upon request

- Connections: Spade terminals, various types of fastons, others on request

- Cable: 3-core PVC

- Cold sector: power cord

- Standard colors: white, gray.

- Metallic braid in tinned copper as mechanical protection and earthing

- Power supply voltages from 100V to 230V

- Construction in class I

- UL approval SA46230 on request

- Testing according to EN 60335-1 and EN 50106

- Construction according to directive 2014/35/UE

- S.I. 2016 No. 1101 (Electrical Equipment (Safety) Regulations 2016) BS EN 60335-1, BS EN 50106

OUR PRODUCTS CAN BE MADE SUITABLE FOR HVAC SYSTEMS ADOPTING PROPANE AS REFRIGERANT