Flexible Printed Circuits - Printed Electronics

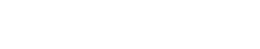

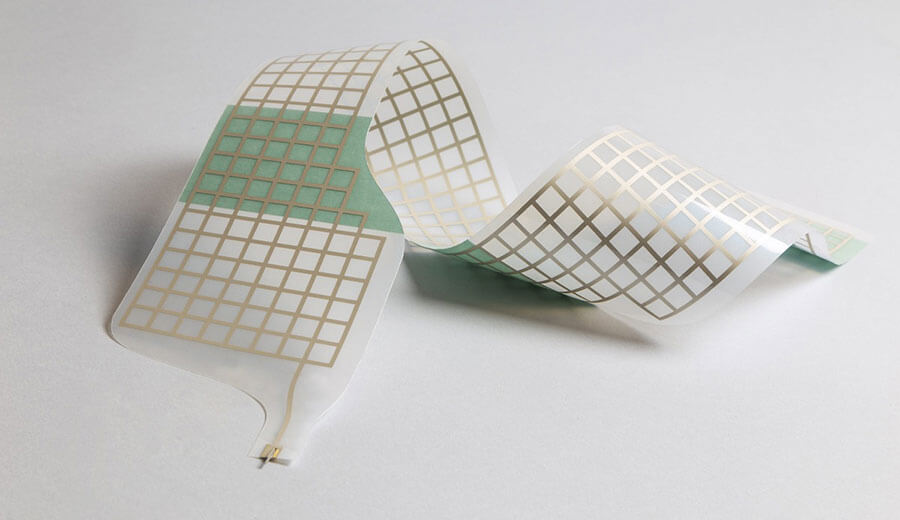

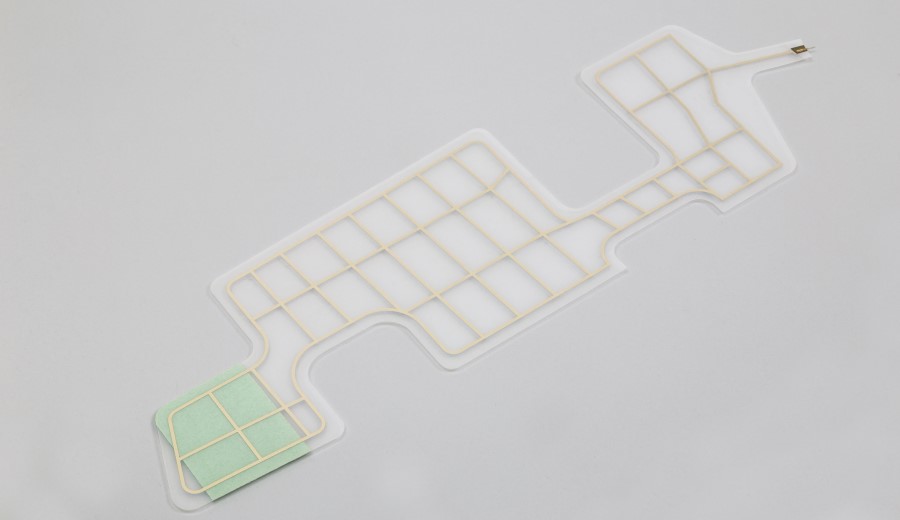

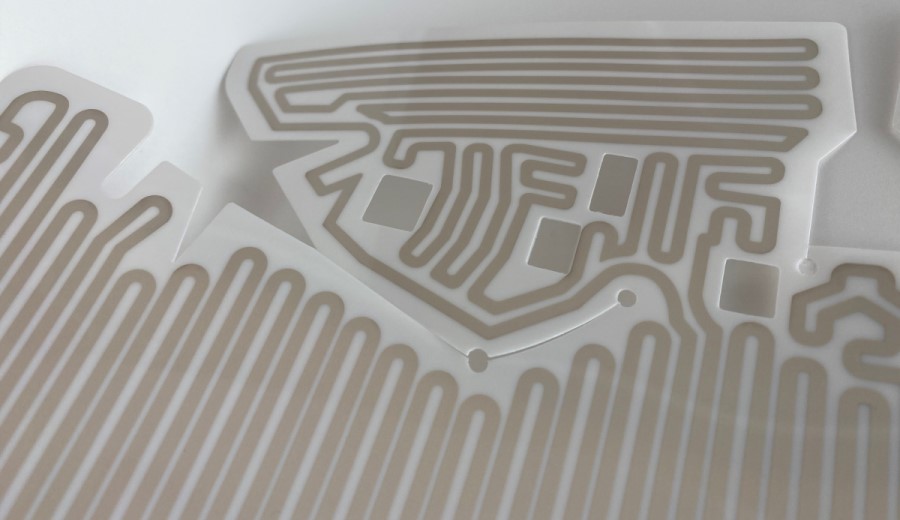

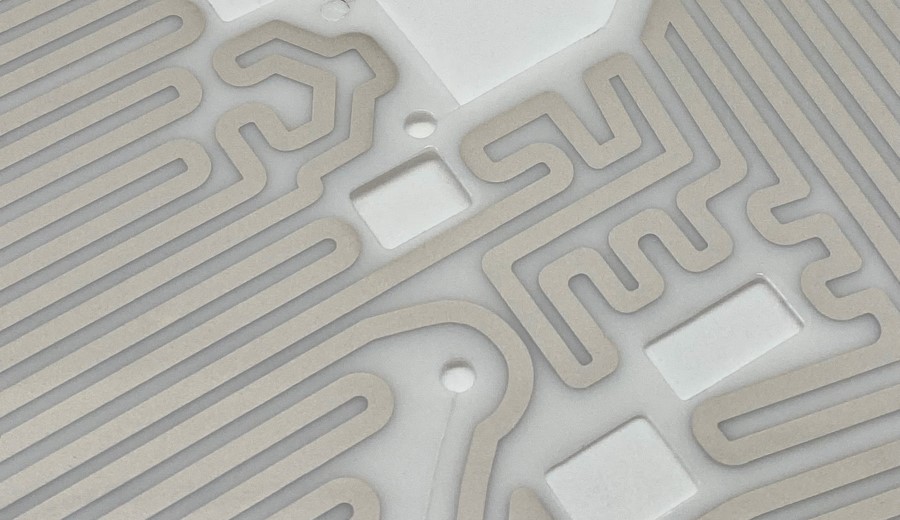

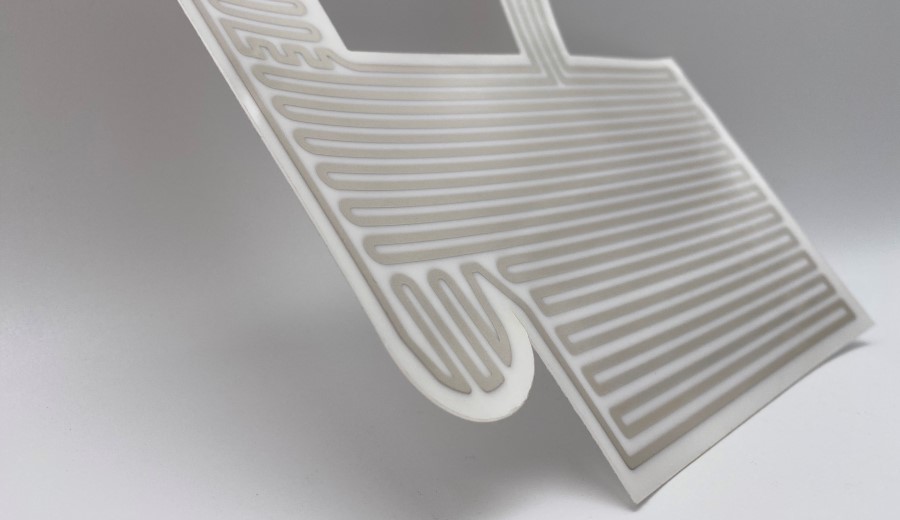

Alper`s flexible circuits, capacitive sensors and antennas are produced by screen printing and allow to obtain extremely thin thicknesses (min. 0.2mm).

Alper's flexible circuits, capacitive sensors and antennas are produced by screen printing and allow to obtain extremely thin thicknesses (min. 0.2mm).

They are used in various fields of application where there is a need to carry a signal, even in current, and where reliability, flexibility without compromising the circuit and minimum thickness are required. In capacitive sensor version these screen-printed sheets are used as a signal for IoT systems in various applications.

These circuits are produced by screen printing, depositing silver-based tracks, suitably mixed with other components, and then protecting them with insulating layers which guarantee high dielectric rigidity of over 3750V. Upon request, the product can be adhesive, even only partially, and can be completed with any type of cable and connector.

The continuous research for new materials and silver pastes has allowed Alper to make the circuit extremely flexible while guaranteeing perfect adhesion of the materials and therefore guaranteeing a long life for its products.

Our production processes guarantee high quality standards combined with a high production capacity. Furthermore, being additive-type production processes, no harmful waste is produced for the environment and for humans.

- Maximum dimensions: 1000x600mm (customized measures available on request).

- application of surface metal films used as earthing, thermal shields or mechanical protections.

- Application of adhesive surfaces using a wide range of specific double-sided adhesives for each use.

- Wiring on customer specification.

- Customer specific design.

- Min temperature: -30 ° C

- Max: 90 ° C (continuously)

- Max: 100 ° C (for short periods)

- Construction according to directive 2014/35/UE

- S.I. 2016 No. 1101 (Electrical Equipment (Safety) Regulations 2016) BS EN 60335-1, BS EN 50106

- RoHS and REACH

Test according to EN 60335-1 and EN 50106