Silver printed resistances – Flexible Electronics

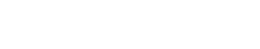

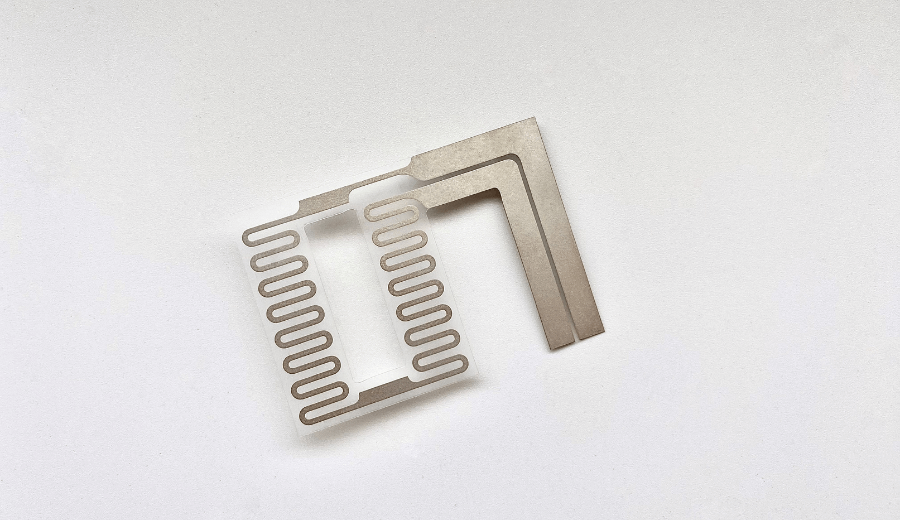

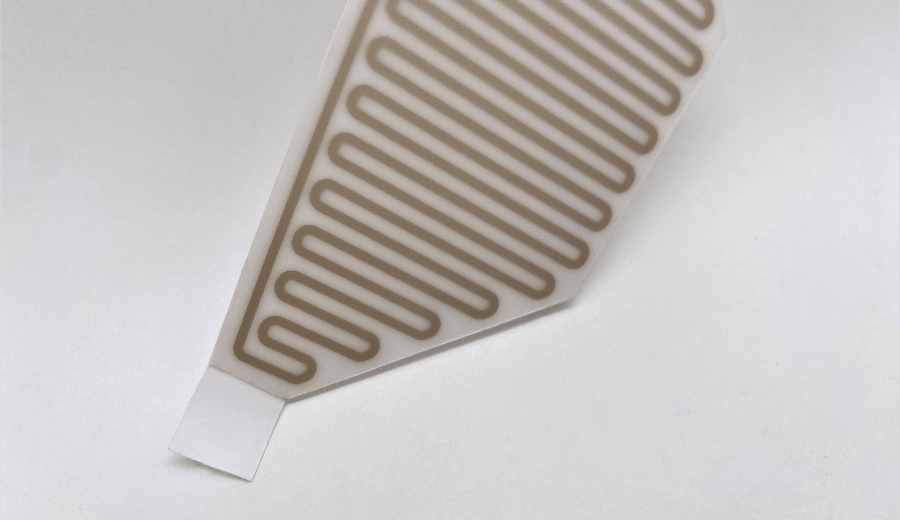

Alper offers its PET-substrate resistances printed not only in Carbon ink but also in Silver-base ink mixture. Silver-ink printed heating elements are preferred for greater precision in the result. In fact, when the customer`s project has a particular design that requires accuracy and attention to details, silver ink heating tracks are preferred. Alper is able to replicate all shapes, even the most complicated and complex.

Alper uses conductive and innovative silver inks for screen-printing. The choice of ink and its conductivity determine the efficiency of the heater, so Alper chooses only top-quality raw materials that allow the heaters to perform at their best.

Contact ALPER to find all the possible applications

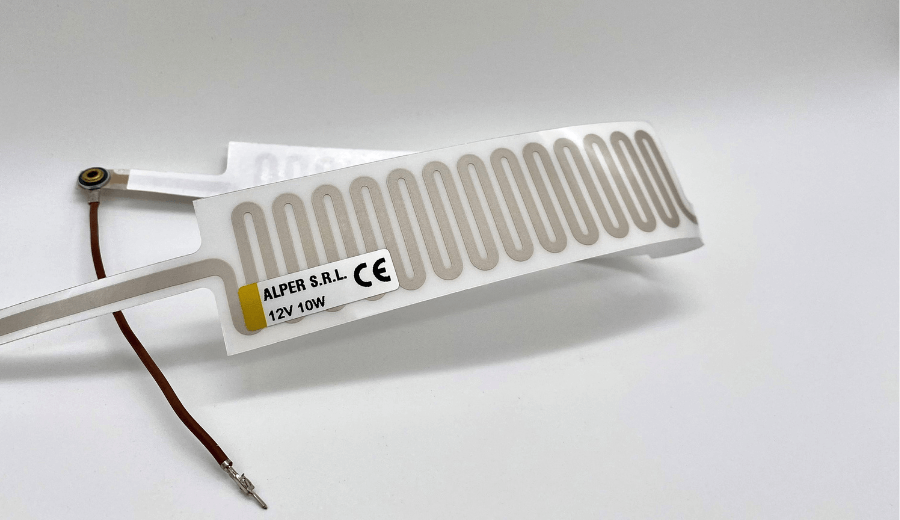

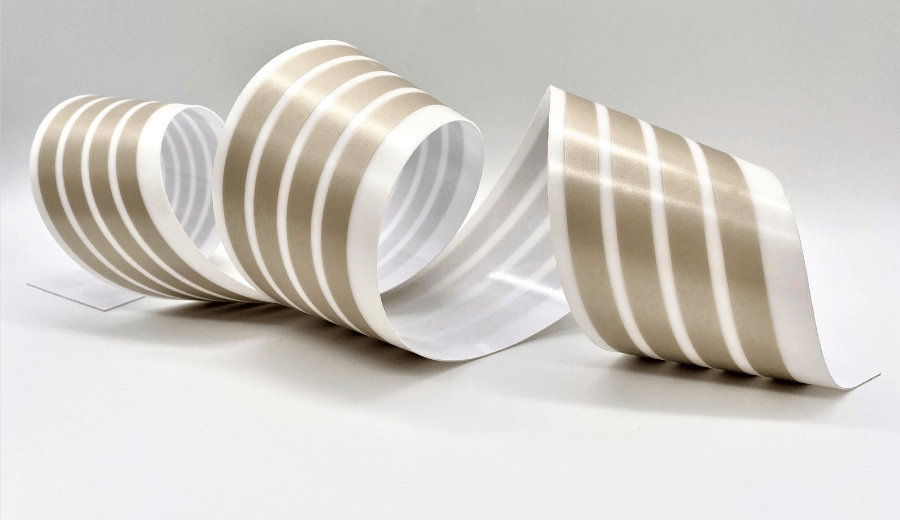

Alper uses printing technologies consolidated over time and together with the innovative intent, has the opportunity to enter in new sectors, such as Printed Electronics. One of the most interesting applications of this technology is represented by resistances printed with silver ink. These heaters are produced through printing and deposition processes that allow to obtain extremely flexible heating elements that can be adapted to the needs of multiple applications.

The silver ink used to print these resistances is composed of nanometre silver particles suspended in a fluid. This type of ink is able to adhere to a wide range of surfaces, including plastic substrates such as PET which is the one used by Alper. Once printed on the PET substrate, the ink is baked to remove the volatile component and consolidate the silver particles into a compact and flexible structure. The result is a highly conductive and flexible resistance that can be easily integrated into a wide range of applications.

There are many applications for silver ink screen-printed heating resistances. Thanks to their flexibility and ability to adapt to non-flat surfaces, these heating elements are particularly useful in applications where flexibility is a requirement.

In summary, resistances printed with silver ink represent one of the most interesting applications of Printed Electronics and Alper is happy to be the pioneer at European level by promoting this still little-known technology. Thanks to their flexibility, adaptability and ease of integration, these heaters are able to revolutionize numerous sectors, from medicine to wearable technology.

- Maximum dimenions: 1000x600mm (other sizes available on request).

- Power and supply voltages on request.

- Best temperature distribution.

- Various thermal protections available such as thermal fuses,thermal protectors, probes and sensors.

- Use of surface metal films used as earthing, thermal shields or mechanical protections.

- Application of adhesive surfaces using a wide range of specific double-sided adhesives for each use.

- Wiring upon customer specification.

- Class I or II construction.

- Customer specific design.

- Min temperature: -30 °C; Max: 90 ° C (continuously); Max: 100 ° C (for short periods)

- Construction according to directive 2014/35/UE

- S.I. 2016 No. 1101 (Electrical Equipment (Safety) Regulations 2016) BS EN 60335-1, BS EN 50106

- RoHS and REACH

Test according to EN 60335-1 and EN 50106