.png)

Printed Electronics (PE)

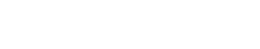

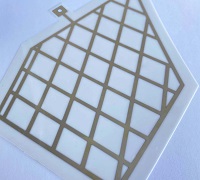

Alper is a company specialized in the production of thin, flexible and lightweight heaters. The technology with which heating elements are produced is by screen printing. Alper is a company that focuses on innovation. Alper's screen printing experience has allowed the company to enter the field of electronics. Alper provides state-of-the-art technological circuits. Printed Electronics (PE) produced by screen printing on flexible PET support represents an innovative technology for the production of electronic circuits on flexible materials. Screen printing is a particular printing process that uses a frame with a stretched mesh to transfer ink onto a substrate. Alper uses thin, durable PET as a support to Printed Electronics (PE). In many applications, first of all the automotive and not least household appliances, entire groups of complex wiring harnesses are starting to be replaced with simple and light PET strips with silver circuits. This technique allows Alper to produce flexible printed circuits (FPC) that can be integrated into devices and appliances of various types. In addition, the Printed Electronics (PE) produced by screen printing on PET support is characterized by a low production cost and high precision in the molding and positioning of the circuit elements.

What is printed electronics?

What is printed electronics?

Printed Electronics (PE) are conquering an increasingly large slice of the global market. At European level, more and more investments are being made in research and development of new projects containing it. The direction of the future is defined, we are moving towards an increasingly technological and cutting-edge world with the implementation of digital to support objects to help us in everyday life. Printed Electronics (PE) is a technology that allows to create electronic circuits on flat supports, not only rigid but also flexible such as, for example, those produced by Alper. This emerging technology with high technological content supports the IoT (Internet of Things), the process that connects multiple physical objects through the Internet.

What substrate is used in printed electronics?

The Printed Electronic (PE) sector is very wide and covers various types of materials and printing. The screen-printing technique used by Alper is an ancient methodology, consolidated and perfected over the years, adapting to the latest needs. With the additive manufacturing process, material is added and therefore waste is limited. Alper's Printed Electronics (PE) use a thin, light and flexible polyester (PET) substrate. It is treated in a special way to make the sheet the perfect adherent base for silver ink molding. PET lends itself to being the appropriate material as a substrate because it is flexible but robust, in fact it has a good resistance to bends and bending, also adapting to applications on curved surfaces. The addition of adhesive on a surface allows perfect adhesion to the application.

perfect adhesion to the application.

Where is Printed Electronics used?

Printed Electronics (PE) is a widespread technology and is present in various sectors, such as the consumer electronics industry, automotive, aerospace, marine industry and medicine. But also, other applications such as: capacitive sensors, sensors for detecting liquid leaks, anti-burglary systems for sirens and ATM, smart clothing and of course many others still in the prototyping and development phase.

Contact us for more information

What are the benefits of using flexible printed electronics?

Printed Electronic (PE) offers numerous advantages that can be appreciated from its use or implementation in products. The first feature that you notice at a glance is the shape of the flexible printed circuit: they are compact and lightweight. In production, greater printing accuracy, reduced costs and increased speed in sample and prototype production are visible. In addition, printed technology makes it easier to produce circuits with different functions such as sensors, membranes, and control devices. IoT technology is easily implemented to make objects intelligent.

How does Alper manage the environmental impact of the production of flexible electronic circuits?

Alper's printed electronics are a completely additive process that does not involve environmentally harmful waste or wastewater. Is used only what is needed and recovered any surplus. It is therefore a healthy production process for people and the environment.

Do you have a project? Talk with our expert team

Alper therefore brings its contribution to Printed Electronics (PE) and to the sectors that use them. Alper technology is flexible in materials as well as in production. Alper provides solutions that meet the various needs by shaping the circuit with all the required features on customer request. Thanks to continuous research aimed at improvement, Alper is at the forefront and guarantees reliable, high-quality and long-lasting flexible solutions.

Do not hesitate to contact us for more information. We are at your disposal