Ultra flat silicon heating elements are produced by chemical etching (etch foil technology)

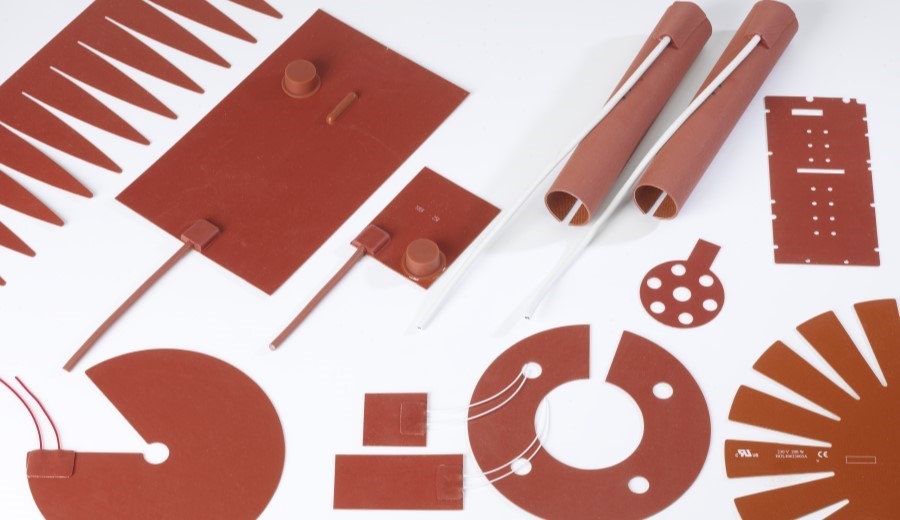

The ultra-flat Alper silicone heaters are produced by chemical etching and allow to reduce the thickness of the heating element to the minimum (min. 0.8mm).

They are used in various fields of application such as aerospace, naval, dishwashers, hobs, kettles, drum heaters and many others.

The ultra-flat Alper silicone heaters are produced by chemical etching and allow to reduce the thickness of the heating element to the minimum (min. 0.8mm). They are used in various fields of application such as aerospace, naval, dishwashers, hobs, kettles, drum heaters and many others.

The technology, unique in its kind, allows to reduce the thickness of the heating element to a minimum value while allowing a very intense power density with continuous working temperatures up to 200 °C with peaks of 230 °C.

The reliability over time in extreme conditions of silicone make this product the best choice in the professional and medical sector.

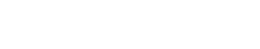

The silicone heating elements can be supplied with slots, holes, traction belts and customizations on request.

On request also a wide range of accessories such as fixed and adjustable thermostats, probes, pt100 and pockets for housing probes.

- Maximum dimensions: 940x3000mm (other sizes available on request).

- Power and supply voltages on request.

- High temperature uniformity.

- Various thermal protections available, such as thermal fuses, thermal protectors, probes and sensors.

- Application of adhesive surfaces using a wide range of specific double-sided adhesives for each use.

- Wiring on customer specification.

- Class I or II construction.

- Customer specific design.

- Min temperature: -60 °C

- Max: 200 °C (continuously)

- Max: 230 °C (for short periods)

- Construction according to directive 2014/35/UE

- S.I. 2016 No. 1101 (Electrical Equipment (Safety) Regulations 2016) BS EN 60335-1, BS EN 50106

- UL approval E466385 on request

- RoHS and REACH

Test according to EN 60335-1 and EN 50106